Think More for You

Founded in 1992, Shin Mold has focused on die-casting mold design and manufacturing for over 30 years as an expert that integrates design, development and production.

Backed by profound design power and years of technical experience, we not only meet customer's needs for mold, but also detect potential issues of mold timely and propose corresponding solutions to assist customers in mitigating possible risks.

Shin Mold deliver more than just molds, it is also a meticulous craftmanship and considerate service. Efficient and smooth die-casting production is the solid experience that every customer has with Shin Mold's mold and it is also incident to reduction of operating cost and acceleration of overall competitiveness, these tangible advantages make Shin Mold a highly trustworthy partner in dis-casting manufacturing.

QUALITY FIRST

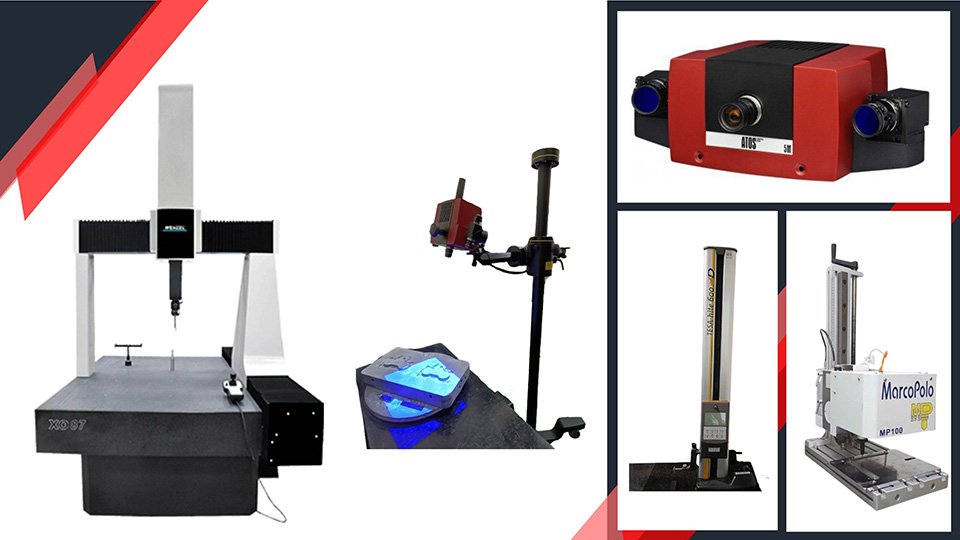

In response to the diversified demands, Shin Mold continuously invest state-of-the-art equipment to enhance machining capabilities and production efficiency, improve precision and quality stability, and broaden process diversity. Our die casting mold capability ranges from 125T to 1650T, enable us to respond agilely and flexibly to meet machining requests from varied customers.

Quality Assurance

We firmly believe that quality is built upon long-term dedication and unwavering commitment. Upholding our core philosophy of "Quality First, Precision Driven", we fully implement international quality management systems from the design stage to final delivery. Each process is carried out in accordance with standard operation procedures and quality inspection protocols, we establish traceable quality records and continuous improvement mechanisms, enforcing stringent checks at every step, with zero-tolerance for compromise.